Plugging braking of induction motor pdf

View EEM 355 – Mechatronic System Part II 2018-2019 – AC drives 2.pdf from EE K260 at University of Science, Malaysia. EEM355 Mechatronic Systems AC Induction Motor Drives 2 …

Plugging can be used for braking, if the motor is a synchronous induction motor and only if the machine is working as an induction motor. DC motors A motor and its load can be brought to rest quickly by using either of the following:

The reversal of direction of rotation of motor is the main principle in plugging of motor. In case of an induction motor, it can be quickly stopped by interchanging any two stator leads.

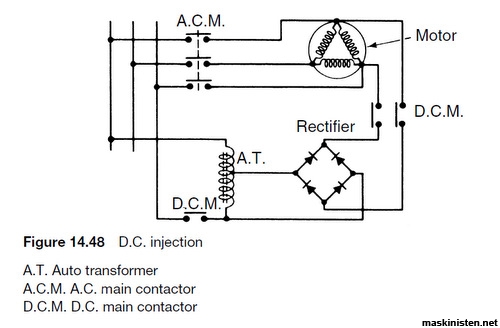

DC injection braking is a method of slowing AC electric motors. A DC voltage is injected into the winding of the AC motor after the AC voltage is disconnected, providing braking force to the rotor.

The braking time is a function of the system inertia, load torque and motor rating. The field circuit is left connected to the supply. The only danger is that if the supply fails, braking also fails. If the field is left connected across the armature, then initially the braking

1. Braking, n. m. it can be seen that if the power converted is negative (from 1 . Torque is positive whilst speed is negative. Considering the power conversion equation . P = τ ω) then the airgap power is positive. i.e. the powe r is flowing from the stator to the rotor and also into the rotor from the mechanical system. This operation is also called . plugging. 2. Motoring, . This

Plug reversal and plug braking 220 Injection braking 221 Speed Control 221 Pole-changing motors 222 Voltage control of high-resistance cage motors 223 Speed control of wound-rotor motors 224 Power Factor Control and Energy Optimisation 225 Voltage control 225 Slip energy recovery (wound rotor motors) 227 Single-Phase Induction Motors 227 Principle of operation 227 Capacitor-run motors …

Plugging induction motor braking is done by reversing the phase sequence of the motor. Plugging braking of induction motor is done by interchanging connections of any two phases of stator with respect of supply terminals. And with that the operation of motoring shifts to plugging braking. During plugging the slip is (2 – s), if the original slip of the running motor is s, then it can be shown

The Braking of Induction Motor is more popular in hoists than the dc motor, due to this feature. The methods of feeding a dc supply to the stator are depicted in Fig, 1.50. It may be provided by a dc supply using a limiting resistor R 1 in the circuit for controlling dc excitation.

A DC motor can be stopped more rapidly by using the method called.Induction Motor Braking Regenerative Plugging Dynamic Braking of Induction Motor. We know that there are various types of motors availableDC motors.

For this two method for braking electric motor system are d.c injection and plugging is suitable application to stop a drive efficiently depend on our system and design. Braking system for electric motor

Studying of braking process in the Alternating Current (AC) motors has a great importance due to the need for reducing the braking and stopping time. In many applications, it may be necessary to use a three-phase induction motor on a single-phase supply system. The aims of this study are to

Plug-Braking Mode 8. High-Torque Induction Motors 9. Single-Phase Induction Motors 9.1. Principle of Operation 9.2. Types of Single-Phase Induction Motors 10. Self-Excited Induction Generators Glossary Bibliography Biographical Sketch Summary Since its invention by Nikola Tesla in 1888, the induction motor has been built in vast numbers and has become the most important workhorse in …

3/4/2015 Induction Motor Braking Regenerative Plugging Dynamic Braking of Induction Motor Electrical4u Plugging Braking of Induction Motor Plugging induction motor braking is done by reversing the phase sequence of the motor. From the figure beside we can see that the torque is not zero at zero speed. then it can be shown in the following way. And with that the operation of motoring …

braking during the deceleration of an induction motor and analyze various aspects during the braking process. This will help in the further development for the “All Electric Ship”

The electric braking of a DC motor is of three types, (i) Rheostatic or dynamic braking, (ii) Plugging or reverse current braking and (iii) Regenerative beaking. (i) Rheostatic or dynamic braking: In case of DC shunt motors , armature is disconnected from the supply and a …

Thus during the plugging, the motor acts as a brake. Note : The method can be applied to both squirrel cage as well as wound rotor induction motors. One important aspect about plugging is production of very high heat in the rotor.

Three Phase Induction Motor Breaking Methods ( 3 Types)

Troubleshooting AC motors and startersMotor braking

Induction Motor Braking Regenerative Plugging Dynamic Braking of – regenerative braking of induction motor Source FOUR-QUADRANT OPERATION AND REGENERATIVE BRAKING (Motors And Drives) – Operation of d.c. motor in the four quadrants of the torque-speed plane

Plugging. Plugging is defined by NEMA as a system of braking in which the motor connections are reversed so that the motor develops a counter torque that acts as a retarding force.

17/03/2015 · contents Induction motor braking can be done by different methods, which are i. Regenerative braking of induction motor ii. plugging Braking of induction motor iii. Dynamic braking of induction motor is further categorized as a) AC dynamic breaking b) Self excited braking using capacitors c) DC dynamic braking

Induction motors are optimal for uni-directional and continuous operation such as a conveyor system. Easy Operation All you need is to connect a capacitor and plug the motor into an AC power supply and the motor can be easily operated. (No capacitor is needed for a three-phase motor.) Extensive Lineup The World K Series and BH Series are available. We have models with an output power range of

In practice, for reversing drives where braking and starting up of induction motor in reverse direction comprises stages of the same continuous process, plugging is advantageously employed. The plugging operation can also be explained with the help of quadrantal diagram shown in Fig. 1.103 (c).

· Regenerative Braking · Plugging or reverse voltage braking · Dynamic ( or rheostatic ) braking : a) ac dynamic braking b) Self-excited braking using capacitor c) dc dynamic braking d) zero-sequence braking Regenerative Braking · Ìf an induction motor is forced to run at speeds in excess of the synchronous speed, the load torque exceeds the machine torque and the slip is negative

a.an induction pdf to cad free software motor, i.e. generator and reverse rotation braking and DC braking. Operation, called Operation, called plugging effectively brakes the speed of the rotor.induction motor has been an industry workhorse for electro- mechanical

Dynamic braking of an induction motor is used achieved by switching over its starter to a DC supply and shunting the rotor external resistance. Dynamic brake for induction motors

Plugging induction motor braking is applied by just reversing the supply phase sequence by interchanging connections of any two phases of stator, we can attain plugging braking of induction motor.Due to the reversal of phase sequence, the direction of rotating magnetic field gets reversed. This produces a torque in the reverse direction and the motor tries to rotate in opposite direction.

PDF The paper presents a proposed scheme for fast braking of induction motor drive system. The proposed braking strategy is based on the injection of an AC voltage to the rotor winding from

DC injection braking is a method of braking in which direct current (DC) is applied to the stationary windings of an AC motor after the AC voltage is removed. This is an efficient and effective method of braking most AC motors.

Module 4 AC MOTOR CONTROL Energy recovered is fed back into the mains saves energy and money Plugging Two phases are swapped over until motor stops. Mechanical Braking Springs hold brake shoes against drum stopping the load from turning DC Injection Braking When required to stop, DC is connected to two of the phases. 2/23/2015 2 Direct Current is applied to two supply lines of the motor

25/12/2018 · Induction motor braking regenerative plugging dynamic of what is in induction motor? Quora. Due to the reversal of phase sequence, direction rotating magnetic field gets reversed. Plugging

The motor then runs as an induction generator and dissipates power with subsequent braking effect. If the motor terminals are then short-circuited, magnetic braking follows. A typical basic connection diagram is shown in Figure . Capacitor braking followed by simultaneous magnetic and DC-injection braking may be applied when load inertia is very high.

ELEC4613 Electric Drive Systems 51. Induction motor Drive F. Rahman (EET, UNSW) July 2011 2 In the case of the induction motor, the rotor follows the air-gap flux with a speed which is

A Novel Fast Braking System for Induction Motor P.L. Rongmei, Shimi S.L, Dr. S. Chatterji, Vinod K. Sharma Electric Brakin plug braking, shown in Fig.1, is that changing the direction of revolving magnetic field to oppose the direction of former magnetic field by changing the phase sequence of three- phase voltages supply to the stator windings, and then the motor will be brought to a halt

phase induction motor is required to have a starting mechanism that can provide the starting kick for the motor to rotate. The starting mechanism of the single-phase induction motor is mainly an additional stator winding (start/ auxiliary winding) as shown in Figure 3. The start wind-ing can have a series capacitor and/or a centrifugal switch. When the supply voltage is applied, current in the

ABSTRACT: This paper presents plugging operation of induction motor drives for stopping and speed reversal. Classical direct torque control (CDTC) is known to produce quick and robust response in induction motor drives.

Dynamic Induction Motor Breaking Methods Dynamic braking guarantees that the motor always comes to zero specced safely if we keep applying the break. This is clear against plugging breaking where the motor will continue to accelerate in reverse direction unless this supply is cut off (& possibly mechanical brake applied) as the motor come to zero speed.

Abstract: Induction motor transients under `plugging’ is investigated. A realistic plugging contractor is considered, which includes disconnecting the supply, `coasting’-a period when no voltage is applied, and applying a negative sequence voltage to cause braking.

18/09/2018 · In this video we will study about the Plugging braking of 3 Phase Induction motor.Here we will discuss about reversing the phase sequence of the motor.

induction machine with D.C injection and the permanent magnet brake. Appropriate graphs are plotted in figures 6, 7 Appropriate graphs are plotted in figures 6, 7 and 8.

Plugging of dc motor pdf icyzinemoj.files.wordpress.com

2 increase the braking torque. Rotor resistance control is of course confined to phase–wound rotors with slip rings[9]. The supply voltages before and after plugging are given in – meraki systems manager documentation

braking of induction motor faadooengineers.com

Electrical Braking in Polyphase Induction Motors

Induction Motor Braking and Speed Control Methods Scribd

Linear Machine Eddy Current Braking Techniques

DC injection braking Wikipedia

Braking Methods of 3 Phase Induction Motor electronics

Braking of DC Motors EEEGUIDE

A Novel Fast Braking System for Induction Motor IJEIT

– Electrical Braking of an Induction Motor (Part1) ~ your

Plugging or Reverse Current Braking Circuit Globe

BrakingPlugging electric equipment

A Novel Fast Braking System for Induction Motor IJEIT

Plugging or Reverse Current Braking Circuit Globe

18/09/2018 · In this video we will study about the Plugging braking of 3 Phase Induction motor.Here we will discuss about reversing the phase sequence of the motor.

The motor then runs as an induction generator and dissipates power with subsequent braking effect. If the motor terminals are then short-circuited, magnetic braking follows. A typical basic connection diagram is shown in Figure . Capacitor braking followed by simultaneous magnetic and DC-injection braking may be applied when load inertia is very high.

17/03/2015 · contents Induction motor braking can be done by different methods, which are i. Regenerative braking of induction motor ii. plugging Braking of induction motor iii. Dynamic braking of induction motor is further categorized as a) AC dynamic breaking b) Self excited braking using capacitors c) DC dynamic braking

ELEC4613 Electric Drive Systems 51. Induction motor Drive F. Rahman (EET, UNSW) July 2011 2 In the case of the induction motor, the rotor follows the air-gap flux with a speed which is

For this two method for braking electric motor system are d.c injection and plugging is suitable application to stop a drive efficiently depend on our system and design. Braking system for electric motor

In practice, for reversing drives where braking and starting up of induction motor in reverse direction comprises stages of the same continuous process, plugging is advantageously employed. The plugging operation can also be explained with the help of quadrantal diagram shown in Fig. 1.103 (c).

A DC motor can be stopped more rapidly by using the method called.Induction Motor Braking Regenerative Plugging Dynamic Braking of Induction Motor. We know that there are various types of motors availableDC motors.

Plug reversal and plug braking 220 Injection braking 221 Speed Control 221 Pole-changing motors 222 Voltage control of high-resistance cage motors 223 Speed control of wound-rotor motors 224 Power Factor Control and Energy Optimisation 225 Voltage control 225 Slip energy recovery (wound rotor motors) 227 Single-Phase Induction Motors 227 Principle of operation 227 Capacitor-run motors …

Plugging induction motor braking is applied by just reversing the supply phase sequence by interchanging connections of any two phases of stator, we can attain plugging braking of induction motor.Due to the reversal of phase sequence, the direction of rotating magnetic field gets reversed. This produces a torque in the reverse direction and the motor tries to rotate in opposite direction.

Plugging or Reverse Current Braking Circuit Globe

DC injection braking Wikipedia

The electric braking of a DC motor is of three types, (i) Rheostatic or dynamic braking, (ii) Plugging or reverse current braking and (iii) Regenerative beaking. (i) Rheostatic or dynamic braking: In case of DC shunt motors , armature is disconnected from the supply and a …

ELEC4613 Electric Drive Systems Section 5.1 Induction

A Novel Fast Braking System for Induction Motor IJEIT

Induction Motor Braking Regenerative Plugging Dynamic Braking of – regenerative braking of induction motor Source FOUR-QUADRANT OPERATION AND REGENERATIVE BRAKING (Motors And Drives) – Operation of d.c. motor in the four quadrants of the torque-speed plane

Troubleshooting AC motors and startersMotor braking

Plugging of dc motor pdf icyzinemoj.files.wordpress.com

Induction Motor Braking and Speed Control Methods Scribd

The motor then runs as an induction generator and dissipates power with subsequent braking effect. If the motor terminals are then short-circuited, magnetic braking follows. A typical basic connection diagram is shown in Figure . Capacitor braking followed by simultaneous magnetic and DC-injection braking may be applied when load inertia is very high.

Plugging or Reverse Current Braking Circuit Globe

ELEC4613 Electric Drive Systems Section 5.1 Induction

ELEC4613 Electric Drive Systems 51. Induction motor Drive F. Rahman (EET, UNSW) July 2011 2 In the case of the induction motor, the rotor follows the air-gap flux with a speed which is

Induction Motor Braking and Speed Control Methods Scribd

Transient performance of induction motors under plugging