What is dynamic braking pdf

But Dynamic braking is still possible. Dynamic braking: Dynamic braking in an AC induction motor is also sometimes called DC injection braking. You can even get such brakes to …

braking to reach the maximum deceleration due to the pneumatic brake has been obtained from diagrams of the ERRI report B126 RP25, providing the braking time at …

of brake system wear analysis, servicing of braking systems and completion of work finalisation processes, including clean-up and documentation. All work and work practices must be undertaken to regulatory and legislative requirements.

Train braking is a very complex process, specific to rail vehicles and of great importance by the essential contribution on the safety of the traffic. This complexity results from the fact

In Regenerative Braking the power or energy of the driven machinery which is in kinetic form is returned back to the power supply. Regenerative braking is possible when the driven load forces the motor to run at a speed higher than no load speed with a constant excitation.

Instead, the extra energy is converted into heat using a chopper and a dynamic braking resistor. A further variant is the use of a three-phase braking resistor in direct combination with the motor. Therefore, the resistor is connected to a contactor in the three-phase circuit of the motor.

Braking Resistors for VFDs Application : Ac variable frequency drives are commonly used with a general purpose AC induction motor to form a

Bendix® EC-60™ ABS / ATC / ESP Controllers (Advanced Models) See SD-13-4863 for Standard and Premium Controllers FIGURE 1 – EC-60™ ADVANCED CONTROLLER INTRODUCTION The Bendix® EC-60™ advanced controller is a member of a family of electronic Antilock Braking System (ABS) devices designed to help improve the braking characteristics of air braked vehicles – including heavy …

Powerohm Resistors is pleased to announce UL certification on Dynamic Braking Modules and Braking Kits manufactured for use with Rockwell VFD and Servo Drive Products.

Dynamic Brake Components A Dynamic Brake consists of a Chopper (the chopper transistor and related control components are built into PowerFlex® drives) and a Dynamic Brake Resistor. Figure 1 shows a simplified Dynamic Braking schematic. Figure 1 – Simplified Dynamic Brake Schematic Chopper The Chopper is the Dynamic Braking circuitry that senses rising DC bus voltage and …

DC Injection Braking is a braking system used with 3. PARAMETER MENU PATH DEFAULT NEW VALUE F250 Program→Protection→DC Braking→DC Injection Braking Start Frequency 0.0

Regenerative braking is a system in which the electric motor that normally drives a hybrid or pure electric vehicle is essentially operated in reverse (electrically) during braking or coasting.

The third is to apply an electrical “brake” via a regenerative variable frequency drive (VFD) and/or dynamic braking resistor. Essentially, the dynamic braking resistor is a dumping ground for the energy contained in the rotating system, allowing it to be “bled off” as electrical energy. Because the operational mode has changed from motoring (power flow from VFD source to machine) to

To prevent skidding, a driving dynamic control system such as ESP must be able to control brake activation within a fraction of a second. The return flow pump for the anti-lock braking system produces

Does the locomotive have dynamic brake Yes No * Peak dynamic braking effort (if applicable) _____ at a speed of (km/h) _____ * Please provide a tractive effort/dynamic brake speed curve relevant to this – locomotive (where available) Traction control system _____

What is a braking resistor? The property of resistors to dissipate heat can be used to slow down a mechanical system. This process is called dynamic braking and such a resistor is called a dynamic braking resistor.

Dynamic braking is the use of an electric traction motor as a generator when slowing a vehicle such as an electric or diesel-electric locomotive. It is termed “rheostatic” if the generated electrical power is dissipated as heat in brake grid resistors, and “regenerative” if the power is returned to the supply line.

IMAGINATION DRIVES US CONTENTS Imagination is the world’s most valuable resource. It’s our window to the future, because if we can imagine it, we can

Induction Motor Braking Regenerative Plugging Dynamic

6 Technical Data of Braking Resistors Chokes and Filters

Regenerative braking is an energy recovery mechanism which slows a vehicle or object by converting its kinetic energy into a form which can be either used immediately or stored until needed.

Smooth braking of a motor can be achieved by electric braking. The electric braking of a DC motor is of three types, (i) Rheostatic or dynamic braking, (ii) Plugging or reverse current braking and (iii) Regenerative braking.

Our purpose is to make superannuation and wealth management better in every way for Australian investors and advisers. Investment portfolios that directly align with financial goals. Advanced portfolio management services. Australians are ready for a new approach to managed investments

dynamic braking. Both regenerative and dynamic brakes are most commonly seen on electric or hybrid vehicles, and braking is accomplished by electrically switching motors to act as generators that convert motion into electricity instead of electricity into motion. it through large banks of resistors to dissipate the Traditional friction-based brakes must also be provided to be used when rapid

Dynamic Braking Another method of reversing the direction of torque and braking the motor is dynamic braking . In this method of braking the motor which is at a running condition is disconnected from the source and connected across a resistance.

To figure out braking behavior, simply use the model with a resistor equal to the motor’s DC resistance when stalled; the inductance can probably be ignored except when one is trying to rapidly switch the motor current on and off (e.g. with a PWM drive).

Plug braking, also refered to as dynamic braking, is a safe way to slow down a vehicle with a series motor when the motor direction is reversed. Without plug braking, if the operator reverses direction while the vehicle is in motion the armature will lock up. When the vehicle comes to a halt, then the motor will reverse direction. Reversing the current to the armature while moving causes the

The dynamic brake method typically has a lower upfront cost, but heat generated by resistors can increase cost two ways. If the resistors are indoors, added cooling capacity may …

Dynamic braking is bringing the machine to rest position by dissipating the kinetic energy possessed by the rotor of motor in the form of heat energy through some external resistance. This braking can be implemented by disconnecting the power supply to windings and short circuiting them. The short circuited windings carrying higher magnitudes of current will damage the windings. To limit the

Dynamic braking is the use of the electric motors as generators when slowing the machine speed. It is termed rheostatic if the generated electrical power is dissipated as heat in brake grid resistors, and regenerative if the power is returned to the supply line.

Regenerative braking is a mature technology. Within Europe, there is still a considerable difference between countries in the share of rolling stock that is equipped with regenerative braking, but the share is relatively high already.

Induction Motor Braking The braking is the process of reducing the speed of an induction motor. In braking, the motor works as a generator developing a negative torque which opposes the motion of a …

Seykens et al / Development of a Dynamic Engine Brake Model for Control Purposes 321 computation time. Here, mean value engine models, such as TNO’s DYNAmic …

Dynamic braking is a process in which kinetic energy of the rotor is dissipated in the internal/external resistor as heat energy after disconnecting the main supply.

Dynamic braking resistors (DBR’s) for inverters and DC drive systems. A drive motor can also act as a generator. If the drive system is built so as to allow reverse power to flow then this power can be fed into a resistor, thus taking energy out of the system and causing whatever is driving the motor to slow down.

Dynamic Braking of Induction Motors Slow down a machine by converting kinetic energy stored in the rotating mass to heat energy in the rotor and/or stator windings.

While it is widely accepted that a full Australian Design Rule (ADR) brake test (fully laden test conducted from 100km/h) is the highest standard test, conducting these tests for maintenance and on-road compliance purposes is not practical.

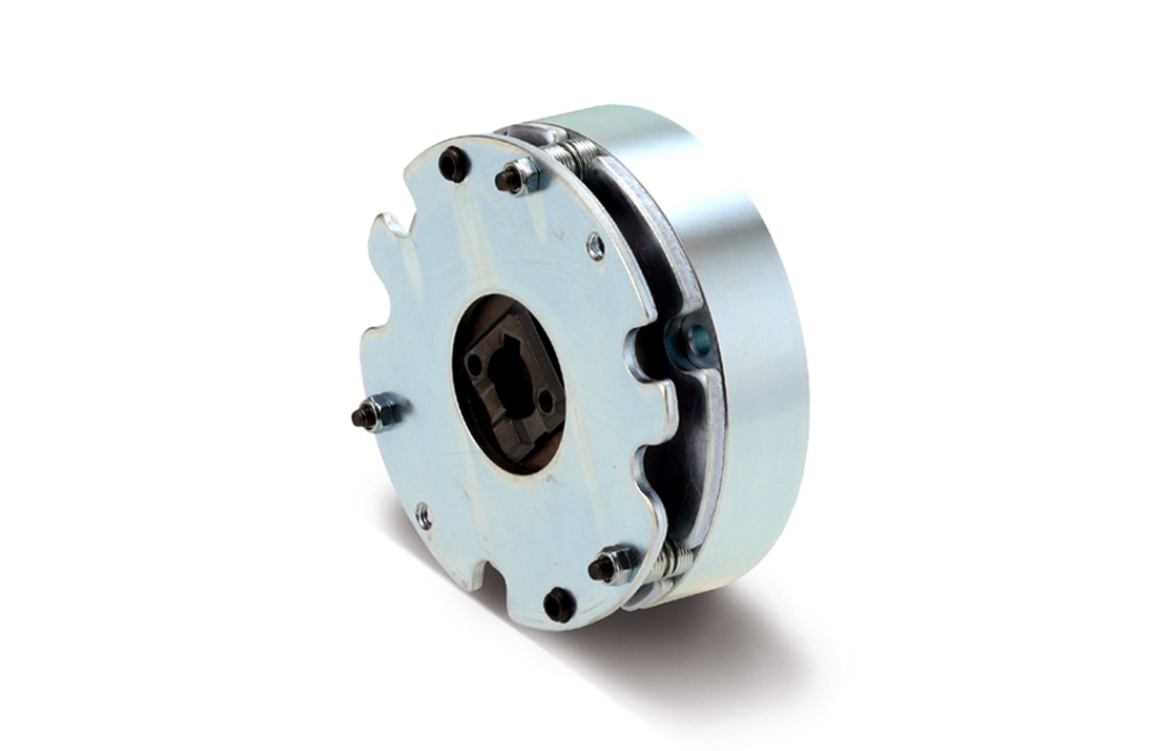

Critical applications use electromechanical clutch and brake devices to stop loads when motor power is removed. However, when motor braking can be less precise, dynamic braking may be a less

3 EBS Introduction The demands made on braking systems are increasing steadily. Therefore, the development and introduction of an electronic braking system (EBS) is a logical step.

In rheostatic or dynamic braking, motor is made to work as generator and all the kinetic energy of the moving mass is converted to electrical energy which is dissipated in the resistance connected as electrical load. In case of shunt motor armature is disconnected from the supply and reconnected across the resistance. DC motor now act as separately excited generator. In case of failure of

Regenerative Braking of BLDC Motors By Daniel Torres, Applications Engineer Patrick Heath, Marketing Manager High-Performance Microcontroller Division Microchip Technology Inc. 2 Different electrical braking scheme Kinetic Energy Kinetic Energy Dynamic Braking OR Regenerative Braking. 3 Regenerative Brake in BLDC motor Kinetic Energy BLDC Hub Motor used in e-bike application While braking

Electric Vehicle Blended Braking maximizing energy recovery while maintaining vehicle stability and maneuverability. Masters Thesis in halmers Automotive Engineering and in European Master of Automotive Engineering

(ET) AC motor theory dynamic braking and regeneration

Basic Dynamic Braking Wiring Diagram for GS3 & GS4 DURApulse AC Drives note: gs2 series ac drives can connect directly to braking resistors, and do not require dynamic braking units For braking. note: smaller-capacity durapulse ac drives can connect directly to braking resistors, and do not require dynamic braking units For braking. other applications require multiple resistors and/or multiple

braking of the semitrailer even if it is equipped with a conventional braking system. Driving stability control (ROP – Roll Over Protection) This function is activated when there is a ri sk of overturning, e.g. when cornering too

The Dynamic or Rheostatic Braking is an insufficient method of braking because all the energy which is generated is dissipated in the form of heat in the resistance. When rheostatc disconnected phase is left open, it is called two lead connection and when the disconnected phase is connected to another machine phase it is known as three load connection.

The “dynamic load transfer” results in ever changing vertical loadings on the tyres, which are additive (+ or -) to static load (due to the force of gravity), and aero forces (lift or

braking resistors (→ MOVIDRIVE® MDX60B/61B system manual, chapter “Braking resistor selection”) • A temperature switch is integrated in the BW…-T braking resistor

Wilwood brake pad compounds are the results of three decades of experience and continual development to provide optimized braking and driver feel for …

Braking and being seen by the traffic behind is of essential importance for motorcycle riders. That is why BMW Motorrad has developed the dynamic brake light as a component of the Strategy “Safety 360°”. It can warn drivers of following vehicles even better about when the motorcycle in front of them is braking.

The aim of this report is to assess the effect of Anti-Lock Brake Systems (ABS) and Vehicle Stability Control Systems (ESP and VSC) on vehicle occupant injury risk and injury severity both through the analysis of real crash outcomes described in mass crash data and a review of current literature. – rainbow six vegas 2 manual pc 9/12/2018 · REVEAL What is plug braking? LIST OF RELATED VIDEOS OF What is plug braking? What is plugging a forklift? What is plugging Crane? What is plugging on a forklift?

vehicle by selectively braking individual wheels and reducing engine torque to bring it back on course. ESC uses components of ABS and traction control to stabilise the vehicle, but unlike ABS and traction

Follow these steps to find the weight transfer – 1. First , find out the weight on the front wheels (left and right) and the rear wheels,the sum of the left front and right front weights will equal the front axle weight.

As against this electric braking is easy, reliable which brings motor to rest very quickly. Three types of electric braking methods are available i) Rheostatic or dynamic braking ii) Plugging and iii) Regenerative braking.

Dynamic braking of 3-phase induction motors through dc injection in commonly used in applications such as cranes and hoists. The paper analyses the performance of a slip ring induction motor with dc injection and derives expressions for the optimum values of injection voltage and rotor resistance.

DC Injection Braking; Dynamic Braking; 1. DC Injection Braking. DC injection braking is a method of braking in which direct current (DC) is applied to the stationary windings of an AC motor after the AC voltage is removed.

Australia’s Best Software Training Experience. Dynamic Web Training, a leader in Microsoft, Adobe, Web Design, Mobile, Graphic Design, eLearning, Lean Six Sigma, Xero Accounting and MYOB software training, provides Australia’s best instructor-led classroom training experience.

Braking is the most important part of speed control.Braking is two types.They are,mechanical and electrical.In mechanical braking we have disadvantages like heat dissipation, mechanical brakes also depends on the skill of the operator.

of dynamic unbalance, the unbalance can be in different axial planes. As a result, while in rotation, As a result, while in rotation, the two unbalanced forces form a couple, which rocks the axis of rotation and causes undesirable

Two Loads DC Dynamic Braking Operation Now coming to the method of operation, the moment when AC supply is disconnected and DC supply is introduced across the terminals of the induction motor, there is a stationery magnetic field generated due to the DC current flow and as the rotor of the motor rotates in that field, there is a field induces in the rotor winding, and as a result the machine

Cressall’s standard ranges of high capacity dynamic braking resistors (DBRs) for regenerative and rheostatic electric motor braking are low cost, easy to specify, quick to install and with ratings to suit inverter drives of any power.

Regenerative braking only promises significant gains in town driving since 62.5% of energy is dissipated in the Metropolitan cycle due to frequent braking. If all brake energy could be regenerated

What is Regenerative Braking DC Series & Shunt Motor

Winder Dynamic testing The execution of specific procedures to test the safety features of a winder during actual operating conditions without compromising the safety of personnel or exposing machinery and equipment to damage . Typical Winder Dynamic tests 1. Winder Safety Circuit Interlocks 2. Speed – distance protection at the upper and lower limits of the wind and in mid-shaft 3. Brake

THE DESIGN OF EDDY-CURRENT MAGNET BRAKES Der-Ming Ma, Jaw-Kuen Shiau Department of Aerospace Engineering, Tamkang University, Danshuei, Taiwan 25137, Republic of China

Electrodynamic braking is a method of small wind turbine control that in-volves short-circuiting the generator stator windings. A short-circuit results in a large back-torque whose magnitude depends on the rate of rotation of the generator and the dimensions and con guration of the generator; two principal con gurations are radial or axial ux designs. In general, turbine manufacturers that use

The braking power, i.e. the power to be dissipated to the brake resistor, corresponds almost to the negative motor power, taking the losses in the motor and the frequency converter into account. The example also shows that the motor power is

Learning & Assessment Resource ATB NSW

Dynamic programming People

Braking a DC brushed motor Electrical Engineering Stack

T HR RS 00811 ST Locomotive Information Pack

Dynamic braking Wikipedia

DEVELOPMENT OF A BRAKING MODEL Railway Research

Electrical Edition Braking Methods of 3 Phase Induction Motor

il patrimonio enogastronomico italiano pdf – BMW Motorrad introduces dynamic brake light.Achieving an

Dynamic Load Transfer OzeBiz

DC Injection Braking Toshiba

Powerohm Resistors Inc. Power Resistors Braking

Train Braking InTech

Braking a DC brushed motor Electrical Engineering Stack

Seykens et al / Development of a Dynamic Engine Brake Model for Control Purposes 321 computation time. Here, mean value engine models, such as TNO’s DYNAmic …

Smooth braking of a motor can be achieved by electric braking. The electric braking of a DC motor is of three types, (i) Rheostatic or dynamic braking, (ii) Plugging or reverse current braking and (iii) Regenerative braking.

Electric Vehicle Blended Braking maximizing energy recovery while maintaining vehicle stability and maneuverability. Masters Thesis in halmers Automotive Engineering and in European Master of Automotive Engineering

DC Injection Braking is a braking system used with 3. PARAMETER MENU PATH DEFAULT NEW VALUE F250 Program→Protection→DC Braking→DC Injection Braking Start Frequency 0.0

of brake system wear analysis, servicing of braking systems and completion of work finalisation processes, including clean-up and documentation. All work and work practices must be undertaken to regulatory and legislative requirements.

3 EBS Introduction The demands made on braking systems are increasing steadily. Therefore, the development and introduction of an electronic braking system (EBS) is a logical step.

Dynamic Braking of Induction Motors Slow down a machine by converting kinetic energy stored in the rotating mass to heat energy in the rotor and/or stator windings.

braking to reach the maximum deceleration due to the pneumatic brake has been obtained from diagrams of the ERRI report B126 RP25, providing the braking time at …

The braking power, i.e. the power to be dissipated to the brake resistor, corresponds almost to the negative motor power, taking the losses in the motor and the frequency converter into account. The example also shows that the motor power is

Dynamic Brake Components A Dynamic Brake consists of a Chopper (the chopper transistor and related control components are built into PowerFlex® drives) and a Dynamic Brake Resistor. Figure 1 shows a simplified Dynamic Braking schematic. Figure 1 – Simplified Dynamic Brake Schematic Chopper The Chopper is the Dynamic Braking circuitry that senses rising DC bus voltage and …

Regenerative braking is a system in which the electric motor that normally drives a hybrid or pure electric vehicle is essentially operated in reverse (electrically) during braking or coasting.

The dynamic brake method typically has a lower upfront cost, but heat generated by resistors can increase cost two ways. If the resistors are indoors, added cooling capacity may …

Dynamic braking is the use of the electric motors as generators when slowing the machine speed. It is termed rheostatic if the generated electrical power is dissipated as heat in brake grid resistors, and regenerative if the power is returned to the supply line.

As against this electric braking is easy, reliable which brings motor to rest very quickly. Three types of electric braking methods are available i) Rheostatic or dynamic braking ii) Plugging and iii) Regenerative braking.

Wilwood brake pad compounds are the results of three decades of experience and continual development to provide optimized braking and driver feel for …

Braking a DC brushed motor Electrical Engineering Stack

Electronic Stability Control roadwise.asn.au

Powerohm Resistors Inc. Power Resistors Braking

Critical applications use electromechanical clutch and brake devices to stop loads when motor power is removed. However, when motor braking can be less precise, dynamic braking may be a less

What Is Regenerative Braking? ThoughtCo

Plug braking, also refered to as dynamic braking, is a safe way to slow down a vehicle with a series motor when the motor direction is reversed. Without plug braking, if the operator reverses direction while the vehicle is in motion the armature will lock up. When the vehicle comes to a halt, then the motor will reverse direction. Reversing the current to the armature while moving causes the

Regenerative braking in trains ClimateTechWiki

Electrodynamic braking is a method of small wind turbine control that in-volves short-circuiting the generator stator windings. A short-circuit results in a large back-torque whose magnitude depends on the rate of rotation of the generator and the dimensions and con guration of the generator; two principal con gurations are radial or axial ux designs. In general, turbine manufacturers that use

A Novel Fast Braking System for Induction Motor

Cranes & Hoists Bonitron Solutions for AC Drives

General Purpose Drive GE Industrial

The aim of this report is to assess the effect of Anti-Lock Brake Systems (ABS) and Vehicle Stability Control Systems (ESP and VSC) on vehicle occupant injury risk and injury severity both through the analysis of real crash outcomes described in mass crash data and a review of current literature.

What is dynamic braking? How to change the motor speed?

SD-13-4869 Bendix EC-60 ABS / ATC / ESP Controllers

3 EBS Introduction The demands made on braking systems are increasing steadily. Therefore, the development and introduction of an electronic braking system (EBS) is a logical step.

IMAGINATION DRIVES US CONTENTS Mazda